Products Description

The fully automatic cardboard box flexible printing slotting and die-cutting machine is a multifunctional cardboard box equipment, which has functions such as automatic conveying of cardboard, printing, indentation, slotting, die-cutting, counting, and paper delivery. It can produce cardboard boxes in large quantities automatically. This carton printing machine can customize its functions according to demand, with the option to choose printing units such as monochrome, two-color, tri color, four-color, and five color. The feeding width of the equipment can also be customized, and the production efficiency of this equipment is high, with a capacity to produce 120/150/200 cardboard boxes per minute. The machine can choose servo control for adjustment. Welcome to provide production requirements, we can manufacture equipment according to your requirements.

Paper feeding unit function:

Automatic mechanical paper feeding, or servo pressure free paper feeding can be selected, with precise and stable paper feeding at high speeds. The paper feeding section adopts electric adjustment, which can quickly replace orders and has a reasonable design structure for convenient and fast maintenance.

Printing unit function:

The printing phase and axial position are controlled by a dual system servo system consisting of a touch screen and electric buttons. The printing plate has an automatic reset function and can be equipped with a high-definition mesh roller and scraper system. The printing pattern is clear and full, and the printing phase is adjusted by servo, allowing for precise adjustment of 0.02 millimeters.

Slotting unit function:

Electric adjustment of slot height, phase, and axial movement adjustment, equipped with pre pressing, line pressing, and quick adjustment design of cutter head. The wheel on the line pressing is wrapped with polyurethane to reduce damage to the hardness of corrugated cardboard.

Die cutting unit function:

The template roller and rubber pad roller are both made of high-quality materials, which are first normalized and then subjected to internal and external cutting processing. After precision machining and hard chrome plating, they are respectively subjected to dynamic balance correction. Install a waste cleaning and conveying device with automatic correction function. Servo controlled linear velocity compensation mechanism can be selected to produce higher precision die-cutting cardboard boxes.

Tags:

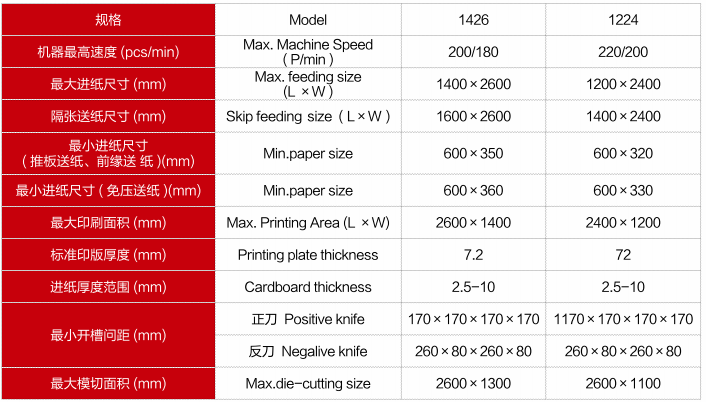

Technical parameter

Bicycle cardboard box

International Exhibition of Ca

Four color ink printing machin

Equipment loading and unloadin