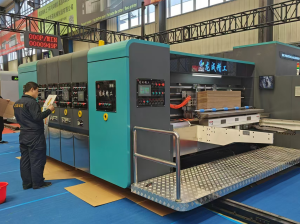

Products Description

The corrugated cardboard flexible printing machine is a type of letterpress cardboard box printing machine that converts the patterns and text to be printed into printing plates, which are installed in the printing unit. The cardboard box printing machine evenly applies ink to the areas of the printing plate with text and images, and then transfers the patterns and text to the corrugated cardboard. After printing is completed, it is slotted and die cut to form. Our cardboard box printing machine prints full and beautiful patterns, and the cardboard box forming effect is better.

Introduction to the functions of corrugated cardboard flexographic printing machine:

1. It has functions such as automatic zeroing, automatic memory reset, and order storage, and can choose remote service.

2. Touchscreen, PLC controller, frequency converter, servo drive, using world-renowned brands such as Siemens from Germany, Bosch Rexroth from Germany, and Yaskawa from Japan.

3. The main transmission gear is made of high-quality alloy steel (20CrMnTi), which is automatically carburized, quenched, and ground by program control to ensure uniform and consistent tooth surface hardness, achieving a standard accuracy of six levels of tooth surface hardness (HRC62-65).

4. All roller shafts have uniform and consistent wall thickness, ensuring smooth and reliable high-speed operation. The roller shaft undergoes multiple quenching and tempering treatments to eliminate stress changes, and the surface is protected by a coating after grinding.

5. The rubber shaft and mesh roller can be tightened with one click, reducing damage to the rubber shaft caused by excessive pressure during manual adjustment.

6. Servo phase adjustment, capable of achieving a minimum fine adjustment of 0.02 millimeters.

Paper feeding unit:

1. The mechanical control leading edge feeding mechanism has the characteristics of fast response speed, high positioning accuracy, stable system, long service life, etc., ensuring the long-term stability of the machine (optional service).

2. Replacing mechanical cam control with electronic cam, the paper feeding wheel shaft and motor shaft are connected by a synchronous belt, eliminating all gaps during the operation of the paper feeding wheel, effectively improving the accuracy of paper feeding, and avoiding the phenomenon of cardboard deviation from left to right.

3. Vacuum suction auxiliary air volume variable frequency adjustment, setting continuous conveying and paper feeding functions, setting up suction function and automatic air volume adjustment.

4. Adopting a unique quick change half wheel structure, the circular surface wear of the paper feeding wheel is uniform and consistent, ensuring long-term consistency of the paper feeding position. When replacing the rubber wheel, it only needs to be directly unloaded, which is convenient and quick to reduce auxiliary time.

5. The order quantity can be set, and after completion, the paper feeding and conveying will automatically stop. The working positions of the left and right baffles and the rear baffle will be electrically adjusted. The automatic paper alignment frequency can be set arbitrarily, which can achieve linkage work with the automatic feeding machine.

6. The front and rear double axis structure of the paper roller ensures accurate and consistent paper feeding.

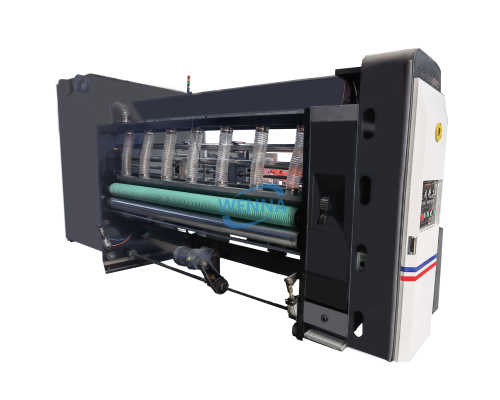

Printing unit:

1. Touch screen and electric button dual system control printing phase and axial position: The printing plate has a erase memory automatic reset function.

2. Set up the ink roller and ink pump start and stop functions in the operation department; Each color group is equipped with an emergency stop protection switch,

3. The paper feeding section of the mesh roller is linked for lifting and lowering, and the gap between the printing plate and the ink is electrically adjusted during ink application; The pressure of the printing plate roller and the paper suction box can be electrically adjusted, and the air volume settings can be adjusted separately.

4. The rubber roller ink distribution system adopts a new technology to ensure compatibility with high dot printing of over 60 lines while ensuring on-site printing.

5. Optional sealing chamber dual scraper leveling mechanism, using an integral ink leveling and anti-seepage device to avoid ink overflow during operation: its special scraper angle makes the transfer of the leveling roller more ideal, making it easy to achieve 100 line dot printing and extending the service life of the scraper and mesh roller.

6. The printing phase is equipped with an electromagnetic clutch braking mechanism, which can automatically lock the gear position when the machine is separated, preventing the zero position of the printing plate roller from being lost.

7. The electric foot switch of the printing plate unit can quickly hang and adjust the plate, making it convenient for plate replacement and cleaning work.

Slotting unit:

1. The dual system operation of human-machine interface and electric button adjustment can complete the adjustment of slot box height, phase, and axial movement.

2. Equipped with a self-locking function pre press quick adjustment mechanism, it ensures long-term accuracy between the disc and shaft, and reduces damage to the cardboard during line pressing.

3. The pressure roller wrapped with high-quality polyurethane ensures that the cardboard hardness is not damaged.

4. Set up synchronous linkage electric axial movement to adjust the upper and lower pressure line wheels, upper and lower slotting cutters, and guide wheels synchronously; Self lubricating wear-resistant guiding mechanism ensures long-term correct displacement and improves durability.

5. The pressure line wheel axle and slotted wheel axle are made of high-quality alloy steel, which is surface polished and plated with hard chrome. They are calibrated on two dynamic balancing equipment, coarse and fine, respectively, to ensure the best balance point is found.

6. select high-quality alloy steel slotting knife with a tooth shaped blade width of 7mm.

Die cutting unit:

1. The dual system control of touch screen and electric button allows for phase and axial adjustment of the die-cutting section. Printing and slotting adjustment buttons are installed on the rear side, and the main unit is equipped with on/off and acceleration/deceleration functions.

2. Adopting a unique built-in differential compensation device, when the outer diameter of the Yuli rubber pad changes, it can automatically compensate for the line speed, ensuring the consistency of the production workpiece specifications and increasing the service life of the Yuli rubber pad.

3. When the die-cutting department starts working, the template roller automatically lifts to the working position, and the Youli rubber pad roller enters the automatic displacement working state; Differential speed design between the Youli rubber pad roller and the template roller; The automatic cutting and repairing mechanism of the device rubber pad can perform multiple repairs on the Yuli adhesive.

4. The template roller and rubber pad roller are both made of high-quality steel, which is first normalized and then subjected to internal and external cutting processing. After precision grinding and hard chrome plating, they are respectively subjected to dynamic balance correction.

5. Install a waste cleaning and conveying device with automatic correction function to prevent deviation and displacement.

6. Servo controlled linear velocity compensation mechanism can be selected to produce higher precision die-cutting cardboard boxes

Tags:

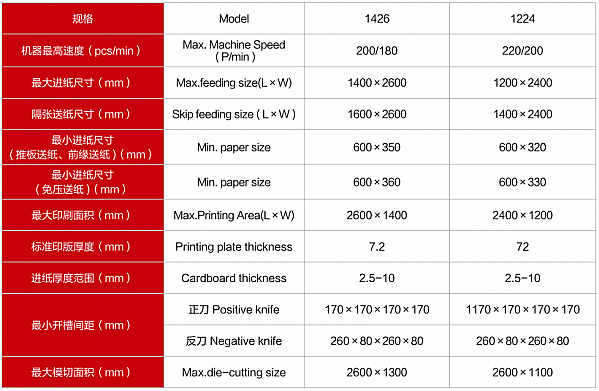

Technical parameter

Bicycle cardboard box

International Exhibition of Ca

Four color ink printing machin

Equipment loading and unloadin