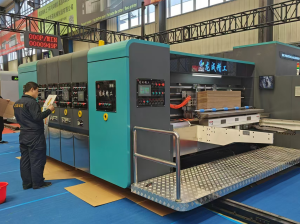

Products Description

Carton HD Printing Machine: Fully Automatic Adsorption HD Ink Printing Machine

The high-definition printing machine for cardboard boxes adopts a pressure free adsorption paper feeding method. The color patterns printed on cardboard boxes have very high clarity and full colors. The equipment can complete printing, indentation, polishing, drying, slotting, die-cutting and other tasks.

Features of high-definition printing machine for cardboard boxes:

High precision: ± 0.3mm registration accuracy, using servo drive, pressure free paper feeding system, and vacuum suction conveying.

High network cable: 130Lpi printing network cable, using a closed ink scraper with ceramic mesh and precision pressure regulation system.

High efficiency: The production process of "paper feeding, dust removal, printing, infrared drying, polishing, drying, die-cutting, waste cleaning, and stacking" is completed in one go, with a production speed of 100 to 150 sheets per minute,

High quality: Adopting CNC intelligent control system and cooperating with Bosch Rexroth in Germany, remote maintenance is achieved through network transmission to ensure long-term stable operation of the equipment.

Paper feeding unit:

1. The servo motor is independently driven, with no gear backlash wear, long service life, and high precision.

2. Vacuum adsorption leading edge paper feeding, variable frequency control of air volume, stable and accurate paper feeding.

3. Extended paper feeding system determines the size of the paper feeding stroke based on the length of the cardboard, improving the accuracy of paper feeding.

4. The pressure free paper feeding system prevents damage to the cardboard during transportation and ensures the compressive strength of corrugated cardboard.

5. Automatic zeroing system, storing commonly used orders, quickly changing orders, and easy to operate.

6. Widened dust removal device, anti-static brush, can remove paper scraps and dust on the surface of corrugated cardboard, improving the printing quality of cardboard boxes.

7. The left and right side baffles are controlled by a computer, with a precise guiding mechanism and stable displacement, and have the function of aligning the sides.

Printing unit:

1. Full process vacuum adsorption, combined with ceramic paper feeding wheel conveyor system.

2. Variable frequency adjustment of suction wind force, and automatic adjustment of air door switch according to the length of corrugated cardboard.

3. Closed high-definition ink scraper system, high-precision ceramic mesh roller, achieves high-precision printing with high dot count, uniform force on the ink scraper, and simple adjustment and maintenance.

4. Pneumatic double diaphragm pump with quick cleaning function, stable ink supply and circulation, easy operation and maintenance.

5. Tilt correction printing roller axis, the tilt error during plate pasting can be quickly corrected on the printing plate roller, making it convenient and fast to follow the printing plate.

6. Clean printing plate memory automatic reset system.

Drying unit:

1. Infrared drying method to avoid ink not drying and affecting printing or gloss effect.

2. Infrared drying box lifting pneumatic control system, the drying box can be quickly lifted.

3. According to the width requirements of the corrugated cardboard, the drying range can be selected to save energy.

4. Adopting an adsorption paper feeding system to ensure the transfer stability of the cardboard.

5. Variable frequency adjustment can be used to adjust the suction wind force, and the air door of the bellows can also be electrically adjusted according to the length of the corrugated cardboard.

6. Optional UV drying system for drying UV varnish on the printing surface of cardboard boxes.

Die cutting unit:

1. Independent servo drive to avoid affecting the printing effect due to die-cutting.

2. Using high-quality die-cutting rubber pads, easy to replace, with a one-way clutch for linear speed compensation function, the cardboard die cut accurately after the rubber pads wear out.

3. During work, the die-cutting rubber pad roller can automatically move horizontally (± 20mm) to prevent repeated cutting marks and extend the service life of the rubber pad.

4. The gap between the rubber pad roller shaft and the die-cutting roller shaft is controlled by pneumatic control. During normal paper feeding, the rubber pad roller shaft descends to the working position, and when the paper feeding stops, the rubber pad roller shaft automatically rises.

5. Rubber pad repair function, increasing the frequency of rubber pad use and reducing consumption.

6. The bottom of the die-cutting is equipped with a paper scraps conveying device, which discharges the paper scraps after die-cutting for easy cleaning.

Stacking unit:

1. Corrugated cardboard can be stacked up to a height of 1600mm.

2. The lifting of the machine is driven by a strong chain. The lifting motor has a braking function to maintain a fixed position and not slide down.

3. The machine automatically lifts and lowers as the corrugated cardboard piles up. When the corrugated cardboard is stacked to a predetermined height, the pneumatic paper lifting mechanism automatically opens to stack the corrugated cardboard, and the corrugated cardboard stacking alarm prompts.

4. Equipped with safety protection devices, the machine is forced not to suddenly slide down, ensuring the safety of operators.

5. Flat wrinkle climbing conveyor belt, corrugated cardboard will not slide.

6. The width of the stacker crane is set at 2200mm and 3200mm

Tags:

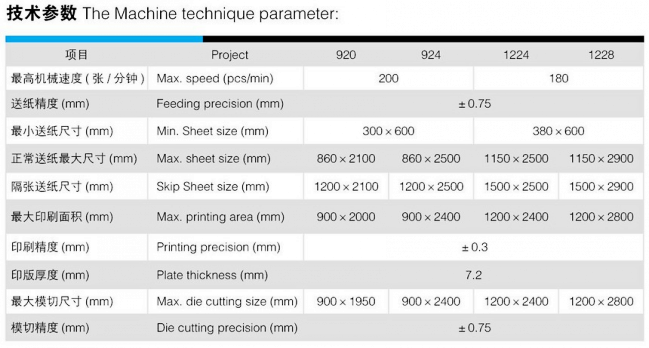

Technical parameter

Bicycle cardboard box

International Exhibition of Ca

Four color ink printing machin

Equipment loading and unloadin