Products Description

Function introduction of fully automatic carton flexographic printing machine:

The fully automatic carton flexographic printing machine adopts servo precision control and vacuum adsorption corrugated cardboard conveying. During the production process, the corrugated compressive strength will not be damaged, and the printing effect is clear. The longitudinal indentation of the corrugated cardboard is aesthetically pleasing. The whole machine can be adjusted with servo control, which provides more precise printing effects and adjustments, and ensures stable equipment during rapid production.

Paper feeding unit:

1. Adopting two sets of suction box servo pressure free paper feeding, it has the functions of fast response speed, high positioning accuracy, good system stability, and efficient guarantee of corrugated cardboard strength. The machine has better long-term stability during use.

2. The adsorption air volume is adjusted by frequency conversion, and can choose between continuous and intermittent conveying functions. The dust removal function can automatically adjust the air volume.

3. The paper feeding wheel adopts a unique quick change structure, with uniform wear and tear. When replacing the rubber pad of the paper feeding wheel, it can be directly loaded and unloaded.

4. The order quantity can be set, and the corrugated cardboard conveyor will automatically stop after completion. The left and right baffles and rear baffles of the paper feeding workbench will be electrically adjusted.

Printing unit:

1. Touch screen and electric button dual system servo control, printed version with memory automatic reset function.

2. The gap between the printing rollers is electrically adjusted, and the paper passing wheel of the printing rollers is adjusted quickly without the need for tools.

3. High definition ink scraper system and ceramic mesh roller can be selected for high-definition printing.

4. The printing phase is equipped with an electromagnetic clutch braking mechanism, which can automatically lock the gear position when the machine is separated, preventing the zero position of the printing plate from being lost.

5. The printing phase adopts servo adjustment, with high accuracy and fast speed, and can achieve fine adjustment of 0.02 millimeters.

Slotting unit:

1. The pre pressing, line pressing, and knife disc quick adjustment mechanisms are configured to ensure long-term accuracy between the disc and shaft, reducing damage to the corrugated cardboard during line pressing.

2. The roller on the pressure line is wrapped with high-quality polyurethane, which prevents damage to the hardness of the corrugated cardboard.

3. Synchronized linkage adjustment of wire pressing wheel, slotting cutter head, and guide wheel.

4. The pressure line shaft and slotted shaft are made of high-quality alloy steel, which is surface polished and plated with hard markings.

5. select high-quality alloy steel slotting knife with a tooth shaped blade width of 7mm.

Die cutting unit:

1. Dual system control with touch screen and electric buttons, capable of adjusting the phase and axis of the die-cutting section. Printing and slotting adjustment buttons are installed on the rear side, and the main unit is equipped with on/off and speed control functions.

2. Adopting a unique built-in differential compensation device, when the outer diameter of the Yuli rubber pad changes, it can automatically compensate for the line speed, ensuring the consistency of the production workpiece specifications and increasing the service life of the Yuli rubber pad.

3. When the die-cutting department starts working, the template roller automatically lifts to the working position, and the Youli rubber pad roller enters the automatic displacement working state. The Youli rubber pad roller is designed with differentiated speed from the template roller; The automatic cutting and repairing mechanism of the device rubber pad can perform multiple repairs on the Yuli adhesive.

4. The template roller and rubber pad roller are both made of high-quality steel, which is first normalized and then subjected to internal and external cutting processing. After precision machining and hard chrome plating, they are respectively subjected to dynamic balance correction.

5. Install a waste cleaning and conveying device with automatic correction function to prevent deviation and displacement.

6. Servo controlled linear velocity compensation mechanism can be selected to produce higher precision die-cutting cardboard boxes.

Tags:

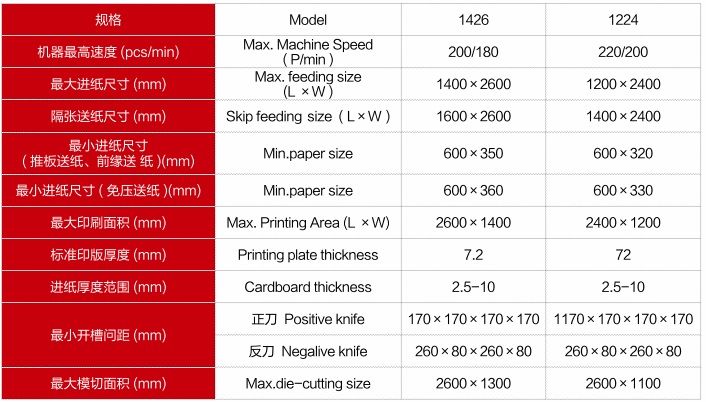

Technical parameter

Bicycle cardboard box

International Exhibition of Ca

Four color ink printing machin

Equipment loading and unloadin