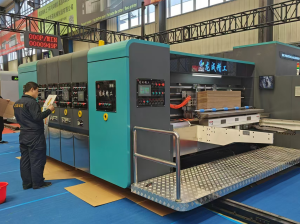

Products Description

Features of automatic corrugated cardboard cross cutting machine:

1. Suitable for mid to high end three, five, and seven layer corrugated cardboard production lines.

2. Automatic tail adjustment device to prevent cardboard from deviating when changing orders (double-layer standard, single-layer optional).

3. Pneumatic balancing of the front and rear upper pressure rollers ensures minimal fluctuations in the operation of the cardboard.

4. The connection between the base and the frame is adjustable, which can precisely adjust the diagonal error of the cardboard.

5. High hardness 20CrMoTi grinding helical gear driven cutter roller, smooth transmission, low noise, long service life.

6. The low clearance blade roller bearing maintains the cutting accuracy of the blade roller for a long time.

7. The small inertia knife roller is matched with the motor, with high cutting speed and low energy consumption.

8. The available spiral serrated knife or spiral straight knife have high hardness and long service life.

9. The gears are lubricated by oil pump circulation, which extends the service life of the gears.

10. The blade is lubricated with oil felt to extend its service life.

11. By cooperating with the management system, it is possible to achieve non-stop order exchange during the dry section, and has the function of switching orders and cutting heads and tails. Industrial computer fault display and system repair function, providing third-party software interfaces.

Tags: Cardboard cutting machine

Technical parameter

Bicycle cardboard box

International Exhibition of Ca

Four color ink printing machin

Equipment loading and unloadin

| Working width | 1800/2200/2500mm | |

| Model | Single layer cross cutting, double-layer cross cutting | |

| Minimum paper cutting length | 500mm | |

| Maximum paper cutting length | 9999mm | |

| Paper cutting accuracy | Uneven speed | ±2mm |

| Uniform speed | ±1mm | |