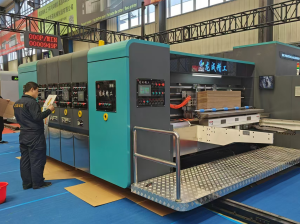

Products Description

Introduction to the functions of automatic tension correction machine:

1. Automated alignment replaces manual moving of the baffle for alignment, using non-contact infrared electric eyes to detect materials and self aligning them at the center or edge of the material. Operators do not need to adjust the position of the baffle by going up or down the bridge. The alignment distance using the baffle is approximately 10-15m, while the automated alignment system can complete the alignment within 3-5m.

2. During paper replacement, there is a self width discrimination device that can automatically switch to central guidance.

3. Equipped with an operation panel, it can display the total width of the single tile paper after bonding, allowing the width to move the original paper holder to achieve the best bonding accuracy of the core paper base. 4. When changing orders, you can directly change orders without slowing down the mechanical speed for changing orders.

5. It can perform the alignment of two layers of single tile wires and use the centering function without the need for paper coordination.

6. With minimal energy consumption and noise, the tension controller can achieve braking effect with only 24V DC.

7. High flatness of cardboard: The tension detection is controlled by the actual tension, which is closer to the tension control of paper.

8. No paper breakage: The brake will control the braking force with a curved square to avoid paper breakage caused by the joint coming over.

Tags:

Technical parameter

Bicycle cardboard box

International Exhibition of Ca

Four color ink printing machin

Equipment loading and unloadin

Mechanical speed: 200-300m/min

Effective width: 1800mm-2500mm

Correction accuracy: ± 3mm

Detection method: Full width infrared eye