Products Description

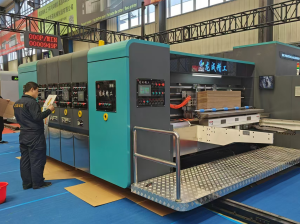

Introduction to Automatic Corrugated Cardboard Thin Knife Longitudinal Cutting and Indenting Machine:

As an important equipment in the drying section of the corrugated cardboard production line, it completes high-quality and precise cutting of cardboard, adopts full computer control, and automatically changes orders, thereby reducing downtime waste and improving production efficiency.

Main features:

1. The upper and lower control system is composed of high-quality human-machine interface and PLC, which can be connected to the production line.

2. Adopting high-precision linear guide rails to ensure cutting positioning accuracy.

3. It can store orders and automatically or manually change orders without stopping the machine.

4. Automatically track the speed of the production line to ensure synchronization, can be connected to the production management system, and has strong compatibility.

5. Adopting thin tungsten steel blades with sharp edges and a service life of over 8 million meters.

6. Sharpening is computer-controlled automatic sharpening or manual sharpening, passive sharpening device, lightweight structure, and easy maintenance.

7. Synchronous belt transmission device, high precision, low noise, and long operating life.

8. The whole machine has a left and right electric correction of 200mm.

Tags: Cardboard cutting machine

Technical parameter

Bicycle cardboard box

International Exhibition of Ca

Four color ink printing machin

Equipment loading and unloadin

| Wide in width | 1800mm | 2200mm | 2500mm |

Speed | 150,200,250m/min | ||

Blade | 5、6、7 | ||

Order change | 1S | ||

Precision | ±0.5mm | ||

Min.slitting | 135mm | ||

Correction range | 200mm | ||

| Total power | 25kw | 30kw | 35kw |

| total power | 3900*1800*2450 (mm) | 4300*1800*2450 (mm) | 4500*1800*2450 (mm) |