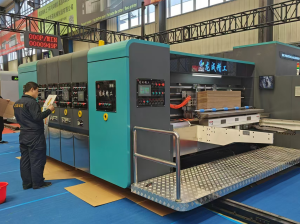

Products Description

1. Automatic lifting and stacking, automatic horizontal output of cardboard; Combined with automated multi station transportation, it is more suitable for large-scale cardboard production

2. Use mesh belt to transport cardboard, avoiding waste of bottom cardboard

3. Automatic batching, cardboard batching output does not affect the high-speed continuous operation of the production line

4. Mixing long and short cardboard to improve the production efficiency of small single cardboard

5. Multiple sets of glass fiber paper are used for brushing and pressing, and the pressing condition can be adjusted according to the length of the cardboard to ensure that various lengths of cardboard are neatly overlapped and conveyed on the stacking machine

6. Variable frequency speed regulation, capable of automatically tracking the speed of the production line

7. With the support of the production management system, cooperate with the automatic fault display of the cross cutting machine to support production management and automatic/manual order replacement.

Tags:

Technical parameter

Bicycle cardboard box

International Exhibition of Ca

Four color ink printing machin

Equipment loading and unloadin

| Model | 1800 | 2200 | 2500 |

| Speed | 250m/min | ||

| Maximum length | 3600mm | ||

| Minimum length | 500mm | ||

| Minimum height | Single layer: 1800mm Double layer: Lower layer: 1800mm, Upper layer: 2200mm (The stacking height shall not exceed three times the width of the cardboard) | ||

| Compressed air | 0.4~0.9MPa | ||