Products Description

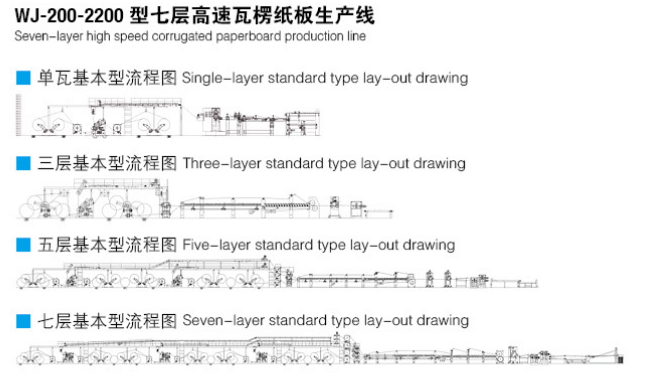

The corrugated cardboard production line is a cardboard box equipment for producing corrugated cardboard, and is also a large-scale equipment in cardboard box machinery. It mainly consists of hydraulic supports (raw paper racks), surface (core) paper preheaters, corrugated single-sided machines, conveyor bridges, coating machines, double-sided machines, longitudinal cutting and pressing machines, cross cutting machines, stacking and receiving paper, as well as adhesive systems, steam systems, electrical control systems, air compression systems and other equipment. Based on the absorption of domestic and foreign technical experience and a wide understanding of user needs, combined with our company's years of experience in producing corrugated cardboard production lines, we have developed and produced high-speed three-layer, five layer, and seven layer corrugated cardboard production lines with a speed of 150-300m/min, including A-rib, C-rib, B-rib, E-rib and other rib types for customers to choose from.

Usage and characteristics:

The corrugated cardboard production line is suitable for large-scale automated production, producing cardboard that meets national standards, with high production efficiency, good cardboard quality, centralized control, easy operation, convenient maintenance, and reduced labor intensity for workers. This production line adopts a new energy-saving method, using high-temperature heat-conducting oil to provide heat source for the whole machine, saving more than 40% of energy compared to other heating methods, greatly reducing energy consumption and effectively compressing production costs. It is an economical production equipment suitable for large and medium-sized cardboard box factories today.

1、 There are two types of brackets available for customers to choose from: axial brackets and non axial brackets.

2、 Waving machine: The corrugated roller has a diameter of 280mm-406mm and uses an electromagnetic speed regulating motor.

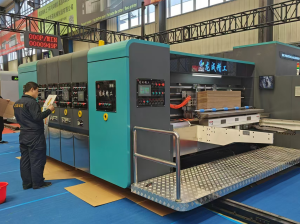

3、 Secondary glue coating machine: easy to adjust, uniform glue coating.

4、 Drying machine: with a total length of 7.8 meters, it consists of 9-18 heating plates.

5、 Forming part: composed of several pairs of forming shafts, with a total length of about 3.8-5 meters.

6、 Vertical and horizontal cutting machines: According to user requirements, two types of ultra-thin cutting machines and ordinary cutting machines can be optionally installed, with high automation and easy operation.

Tags:

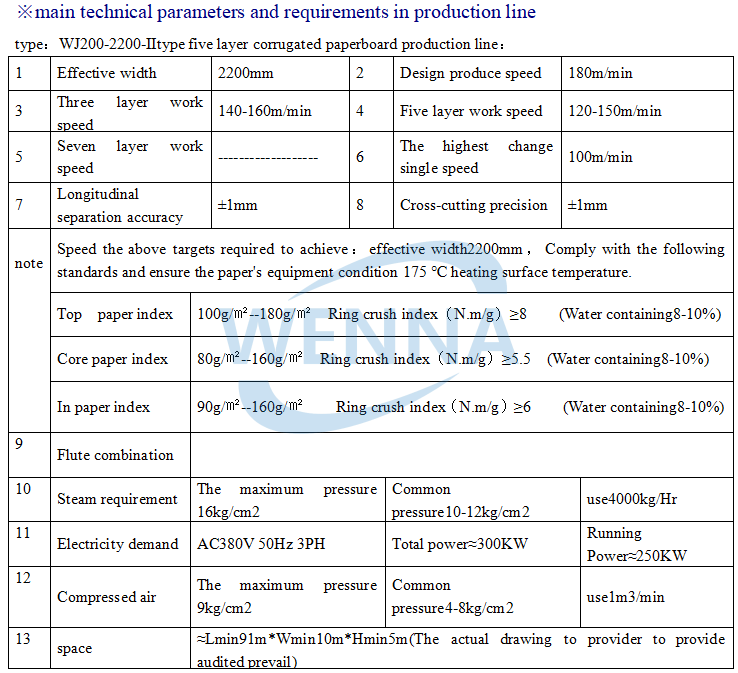

Technical parameter

Bicycle cardboard box

International Exhibition of Ca

Four color ink printing machin

Equipment loading and unloadin