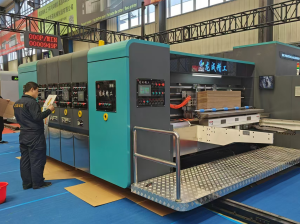

Products Description

Features of automatic die-cutting machine:

1. The die-cutting speed can reach 8000 pieces per hour, and the die-cutting accuracy remains below+0.1mm.

The thickness of the main wall panel is 65mm, and the pressure can reach 300 tons.

3. The paper feeding head has 4 suction nozzles and 4 paper feeding nozzles, with strong suction function and stable paper feeding. The suction nozzle can continuously adjust the suction height angle and air volume of the paper according to its changes, thereby achieving thickness, accuracy, and stability of paper feeding.

4. The advanced coding paper mechanism and main and auxiliary paper feeding devices achieve continuous paper feeding without stopping the machine.

5. PlC program control, equipped with human-machine interface display screen, real-time monitoring of machine operation, and dynamic monitoring of input and output points and various faults of PlC program. The human-machine interface touch screen displays faults and troubleshooting operations very conveniently.

Bottom suction feeder:

The bottom suction feeding unit adopts the suction cup type non-stop paper feeding mode, the pneumatic side push gauge baffle pushes the paper pile together in advance, and the vacuum adsorption method is used to send the cardboard into the press roll, which is not easy to scratch the printing surface.

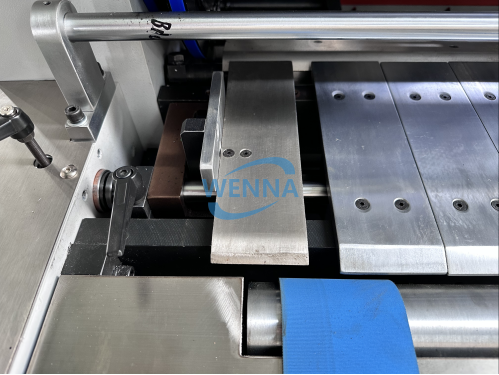

Paper feed frame:

The pneumatic lifting device of the paper feed frame can accurately position the paper when the paper is feed to the front gauge, and the position of the paper can be fine-tuned according to the size of the gripper edge.

Bottom suction push gauge:

The each left and right side also have side positioning push gauge to ensure that the cardboard side positioning is accurate, the paper feed step adjustment using advanced non-stop adjustment.

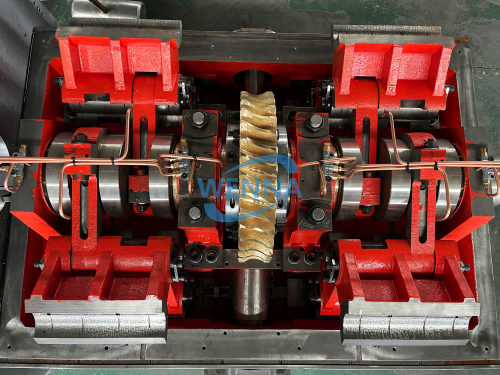

Base Stage:

Worm gear material selection of alloy copper, precision machine tool processing, high precision, high wear resistance, worm gear crankshaft selection of chromium steel, high-frequency quenching treatment, long service life, so with heavy die-cutting pressure, wear and durable.

Double button pressure adjustment:

The main machine adopts the front and rear pressure regulating structure, which mainly saves the time of replenish plate and underlay plate, and improves the working efficiency.

Pause:

Taiwan high precision intermittent divider can ensure high positioning accuracy.

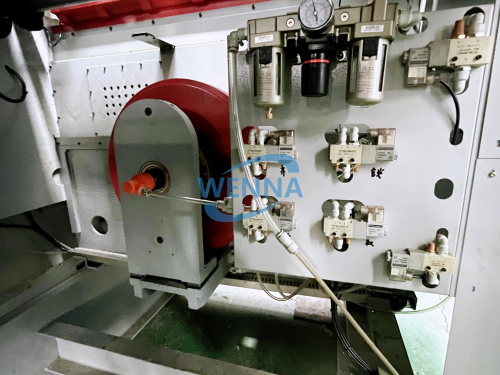

Pneumatic Clutch:

Shanghai Yuyi pneumatic clutch, low noise, reduce pneumatic impact.

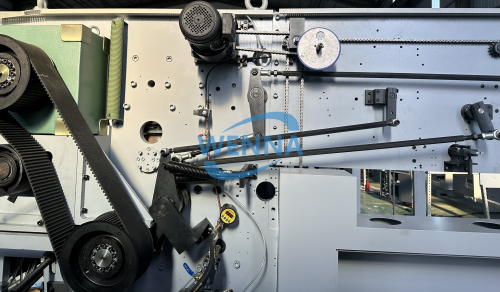

Synchronous belt swing rod transmission:

Use synchronous belt connecting rod drive instead of the chain drive.

Accurate transmission, no sliding when working, with constant transmission ratio.

Smooth transmission, with buffering, shock absorption ability, low noise.

High transmission efficiency and obvious energy saving effect.

Easy maintenance, no lubrication, low maintenance cost.

Tags:

Technical parameter

Bicycle cardboard box

International Exhibition of Ca

Four color ink printing machin

Equipment loading and unloadin